info@tetos.co.kr

Contact Us

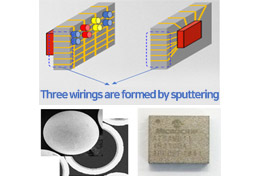

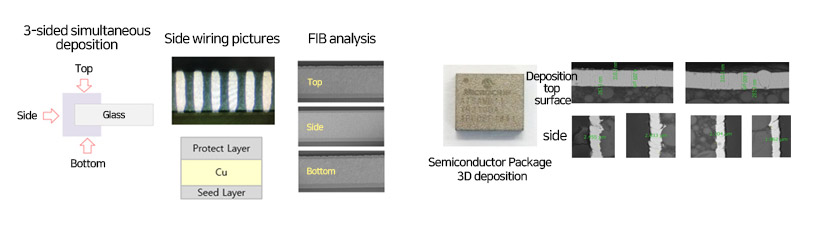

Simultaneous metal deposition on 3 sides of display board (side wiring technology)

— Product Application

ㆍSubstrate side wiring TV

ㆍSubstrate/Ball/Deposition

Simultaneous metal low temperature deposition technology for 3 sides of display substrate

(3D low temperature deposition method & equipment)

— Advantages and Differences

| Low temperature 3D deposition | other companies 150~200℃ / TETOS 90℃ |

|---|---|

| Excellent 3D wiring adhesion | 60/60㎛ Pitch, 5B (ASTM D3359) |

| Semiconductor IC Metal deposition performance | – EMI shielding performance : Ag-Spray 70dB↓/ TETOS 75dB↑ – Top surface vs. Side deposition comparison : other companies 45%↓/ TETOS 60% |

— Applications and Features

| Applied to display products using three-sided substrate deposition | – Possible to realize boards of various sizes / thickness – Excellent deposited film uniformity (tolerance ≤ 5%) – Excellent electrical conductivity through high purity metal deposition |

|---|---|

| Applied to EMI shield product using chip 5-side deposition | – 3 Layer Metal Application (Sus / Cu / Sus) – Various metal types and thicknesses can be applied – High electromagnetic shielding possible (75dB ↑) |

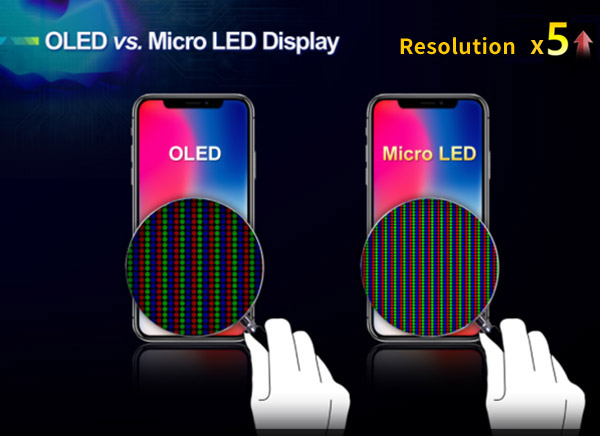

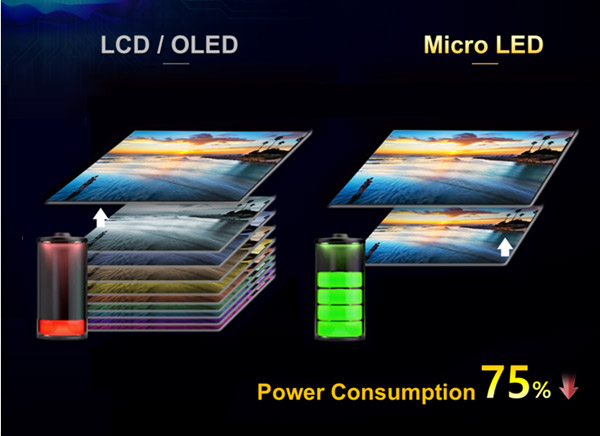

— OLED vs. Micro LED Display

Other Services

-

Wafer Plating

Application : Semiconductor Wafer Bumping RDL/UBM Process Cu Plating Process Cu Plating Equipment Composition Wafer Cu Plating Equipment 3D Design – Composition:

-

Screening/Radiator Film

Screening/Radiator Film — Shielding/heat radiation film deposition — Replace traditional plating with sputtering. Gain quality and price competitiveness by diversifying and simplifying